Symptoms: PDK Failure Light, Rough Gear Changes, Transmission Faults, Emergency Transmission Run Warning on Dash

The Porsche-Doppelkupplungsgetriebe – which translates to Porsche double-clutch transmission or PDK – now that’s when you really need an acronym! A number of Porsche Macan owners have experienced failure of the PDK transmission.

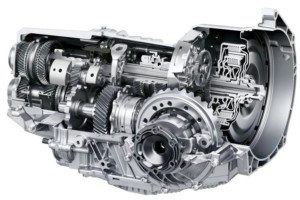

The PDK is an automated manual transmission. Two units matched together – a manual transmission rear section and automated dual clutch front section. The manual transmission rear section is very solid and reliable. Most issues occur with the electronic and hydraulically controlled clutch section at the front of the transmission. Physically, the PDK is a ZF transmission unit that has been around for a number of years. VAG took multiple versions of the transmission and personalized them for their various car ranges. Porsche adapted the software and labeled their version PDK.

There are a number of ways in which the PDK in the Macan can fail. Most show up as a collection of warning lights on the dash and an eventual refusal to do anything. The only viable solution for most people is the replace the PDK – this is very expensive. However, much of the need for replacement of the PDK comes from a lack of understanding, unavailable parts and an unwillingness to dig deep.

Components and Failures

Transmission Control Module – TCM

The connection to the car and communication of instructions to the transmission, come from an external module called a transmission Control Module (TCM). While this rarely has issues, it can become confused and has been the subject of a number of software revisions. Re-flashing the TCM doesn’t usually solve problems, but ensuring you have the latest software revision can’t hurt. This is where diagnostic faults are stored.

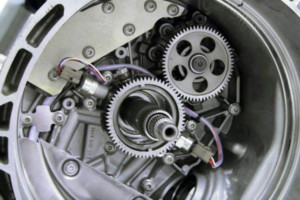

Mechatronic Unit – Valve Body

The TCM sends instruction to the Mechatronic unit or valve body inside the transmission. The Mechatronic unit is a complex series of electronics, hydraulic valves and sensors. These devices are managed by a control module attached to the Mechatronic unit. This is the system which enables gear changes and controls the transmission functionality.

The Mechatronic unit is a common failure point for this type of transmission. In 2009, VW recalled 53000 of them – so there have been many issues in the past. Problems with the Mechatronic unit vary, but commonly include failure to select gears, rough gears changes, etc. The physical components of the transmission are robust, so this unit is often the most economical place to start for most issues.

Sensors

Connected to the Mechatronic unit are a number of sensors throughout the transmission. These determine the operating conditions within the transmission. For example, the temperature of the fluid, the rotational output speed, hydraulic clutch pressure and movement of gears selectors. Failure of these sensors is very common. Early on, Porsche routinely replaced the wiring and trans temp sensor in most of the PDKs.

However, the problem did not go away and has re-occurred on the same transmissions further down the road. The temp sensor problem can show up on almost any model with a PDK.

Clutch

The clutch pack has proven to be very robust and generally does not fail with normal use. Over extended mileage this will become a wear component that will need to be replaced. The failures of the clutch that have occurred, are usually on performance enhanced engines delivering too much torque for the clutch plates. At higher torques, the clutches slip resulting in highly accelerated wear and early failure.

Why do I need to replace the PDK?

The PDK transmissions in the later cars are very complex and the technology involved is a closely guarded secret. Technicians at Porsche are not trained to dissect the transmission and make repairs. They will replace the Mechatronic unit, but often they just replace the transmission as a whole. The components such as the Transmission Control Module (TCM) and the Mechatronic Unit or valve body inside the transmission are often unavailable as parts outside of the Porsche workshop.

The manufacturers do not want it taken apart and it’s often described as a “sealed PDK”. The result from faults is often a new PDK, when in reality, an internal component swap would likely save the whole unit from being replaced. While there is a lot of complex “stuff” in there, the physical components typically don’t break. So, being forced to lash out $12K to $15K for a new PDK, in our mind, is often caused by an unwillingness of people to take the thing apart!

Can You Get Creative?

Creative can often translate to money saving. Removal and disassembly of the PDK is not complex. However, access to parts and the need for a PIWIS to re-initialize the PDK are barriers for the DIY enthusiast. There is an excellent article

here that provides good background, examples of the work and videos of the internals of the transmission.

Having experienced a PDK problem on a vehicle we owned, we got creative. Based on issues with other transmissions, such as the Mercedes Benz, commonly known for valve body failure, we were convinced our issues lay in the physical part of the Mechatronic unit.

Short version – we got a new Mechatronic unit from Audi, replaced the electronics with the original unit from the Porsche, flashed the TCM to match new software levels and hey presto, a perfectly working PDK!

If you have PDK problems and want to try something creative before shelling out for a new unit, you’ll need the help of an expert

independent Porsche repair shop.